There are a number of industries, especially civil and mining, that require building and infrastructure solutions that are both functional and dependable. Protecting your people and assets is imperative for efficiency, safety and success.

There are numerous Shelter options out there, and hundreds of suppliers. Traditional structures, such as steel sheds, deliver functionality, but they are often slow and expensive to build.

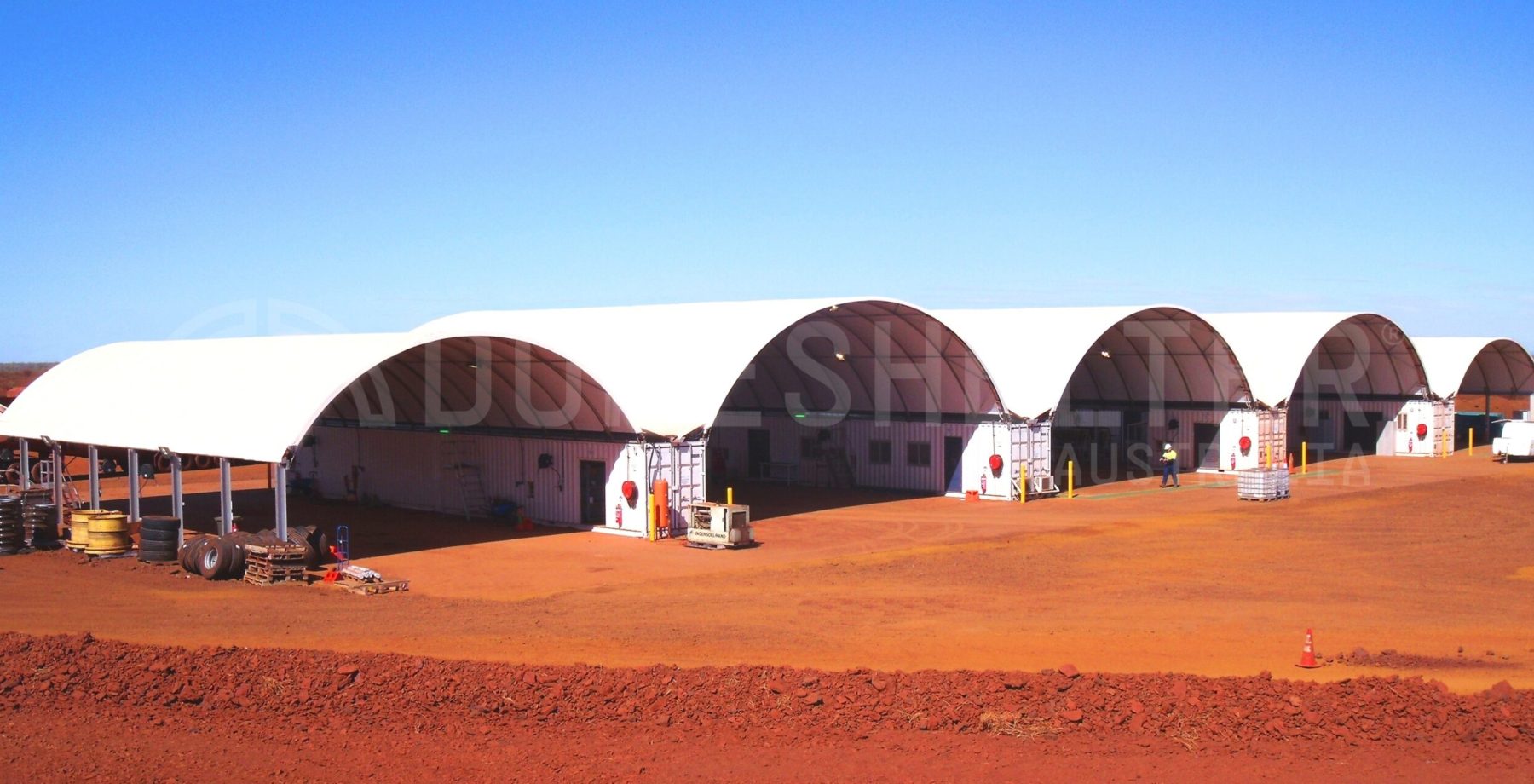

Fortunately, there is an innovative shelter solution that is perfectly suited to civil and mining projects, among a range of other applications. With innovative foundation options that allow structures to be used on long term projects and easily relocated, as well as cost-saving features and a variety of other benefits, they make a perfect alternative Shelter option.

However, in some cases, Fabric Shelters may not be the most suitable solution due to certain variables. So how do you know if it’s right for you?

This article lists some key pros and cons of Fabric Shelters to help you make an assessment.

Pro: Quicker Installation

Most Fabric Shelters, including DomeShelter™ Structures, are specifically designed for easy installation. The modular design of DomeShelter™ Structures’ steel frames means they can be packed easily for delivery and efficiently installed on-site anywhere in the world, often by clients’ own crew.

This sets Fabric Structures apart from other traditional structures such as steel sheds, which often have lengthy installations that have to be performed by qualified contractors, sometimes taking years for construction to finish.

The domino effects of this include:

- Dramatically reduced downtime

- Cost reductions relating to transport of materials, contractor accommodation etc.

- Long-term maintenance savings

Con: Not Permanent

While Fabric Shelters can last decades with proper maintenance, they are considered “semi-permanent” rather than permanent. They generally do not have the same lifespan as steel sheds or other similar structures.

For clients who are seeking a Shelter that will remain in one spot indefinitely, a steel shed or other more traditional permanent building may be ideal. With that said, DomeShelter™ Structures have been known to last in one spot for 20+ years – it’s worth assessing whether the engineering and brand of the Shelter you are researching has a reputation of lasting the test of time.

Pro: Reduced Lead Times

Fabric Structures use significantly less materials and typically don’t require the same lengthy planning and approvals process as steel sheds. Manufacture is efficient and neatly-packaged kits mean easy transportation, all resulting in significantly reduced lead times.

When we have standard-size DomeShelter™ Kits in stock, they can be dispatched in a matter of weeks. DomeShelter Australia has completed past projects, including extremely large shelters such as one at Sunmetals in Queensland, in only a few months, proving the turnaround speed of Fabric Structures.

Con: Varying Range in the Market

There are a series of different companies in the market who offer ‘fabric shelters’, but generally one company’s product differs substantially from the next. The varying shape, size, materials and quality of all the different fabric shelters in the market can make it a confusing product to understand, and if you are making a first time purchase, research is imperative.

‘Fabric Shelter’ may be used to describe any tarp or fabric-based product, such as a small marquee. This could confuse Project Managers who are seeking a high-compliance Shelter for an industrial worksite, causing them to believe Fabric Shelters will not suit their needs. Companies such as DomeShelter Australia, however, specialise not in small, tent-like fabric buildings, but instead manufacture high-quality, durable and fully engineered Structures well-suited to high-compliance worksites.

Pro: Natural, Bright Light

Traditional buildings like steel sheds often require constant artificial light to ensure visibility, and even with overhead lights the corners of the structure may be dark. Fabric Structures are usually constructed using translucent tarp fabric that allows natural light to pass through; this creates a bright and airy internal environment that is safer and more pleasant to work in.

A bright, well-lit internal environment achieved through natural light passing through the fabric also means minimal – if any – artificial lighting is required, which means huge savings on energy bills.

Con: Not Suitable For Extremely Short-Term Uses (<3 Months)

The label ‘Fabric Structure’ can sometimes conjure images of marquees, tents, and other similar structures that are small-scale and held up with pegs and strings. This sometimes creates confusion, with people looking to purchase a structure for an extremely short-term application, such as a marquee for a 2-day festival.

While there are suppliers out there who offer this, manufacturers of ‘Industrial Fabric Structures,’ such as DomeShelter Australia manufacture fully engineered Structures using durable steel and heavy-duty fabric. While these Structures have a unique modular design that allows them to be packaged in kit form and gives them mobility that traditional sheds lack, to erect the structures footings and welding are often required, making them unsuitable for those who are seeking a solution that is closer to a marquee. In addition, they are built to last, so the price far outweighs that of a marquee or tent.

Pro: Flexible Design Configurations

Fabric Structures can be manufactured in a range of shapes and sizes, with different mounting options, end walls, and a variety of other customisations. Rather than a one-size-fits-all approach, quality manufacturers will work with clients to create solutions that are designed to suit their specific needs.

At DomeShelter Australia, we offer fully Fit-For-Purpose Shelter Solutions that are designed with the clients to ensure their needs are met. Our skilled in-house design team have designed and manufactured fully engineered solutions for a range of past clients, including Newmont and Engenium, that were fully customised to provide ultimate suitability and efficiency.

Con: Bad Reputation

The varying range in the Fabric Shelter market not only relates to differing products, but also differing ranges in quality. There are several imported options in the market that are not correctly engineered to withstand Australia’s extremely harsh weather conditions, and are constructed poorly using flimsy materials – these are prone to collapse. Those who witness or see the aftermath of a Fabric Shelter failure may develop a negative prejudice and believe all Fabric Shelters are unsafe and unreliable.

These cheap imported Shelters are usually sought by those hoping to find a shortcut in price; unfortunately, many of these purchasers end up suffering in the long run due to failed Shelters. Quality manufacturers offer in-house engineering and use only the most durable materials in their Shelter manufacture to ensure every Structure can withstand even the harshest conditions. While a more comprehensive design and engineering process may come at a higher upfront price point, safety is paramount.

Get In Touch With A DomeShelter™ Expert

While Fabric Shelters may not be suitable for every customer, there are a number of benefits to choosing a Fabric Shelter over an alternative Shelter Solution that buyers are unaware of.

If you believe a Fabric Structure could be the best choice to solve your Shelter needs, get in touch with a DomeShelter™ Consultant or try our Free 3D Designer to see how a Fabric Shelter could suit you.