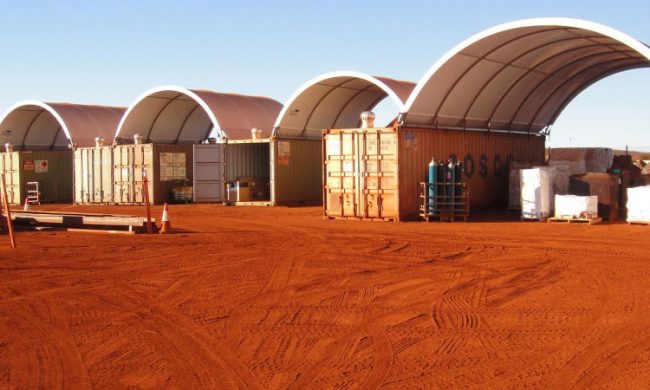

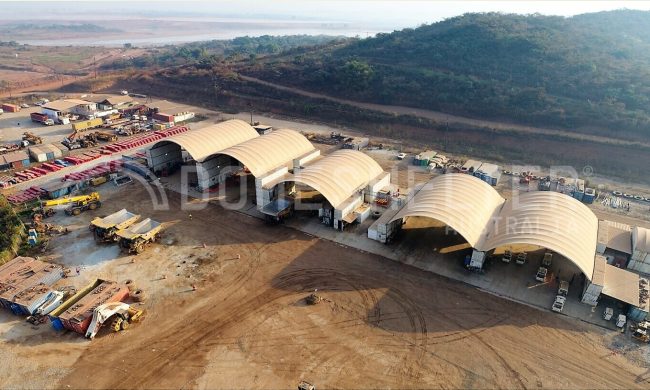

Fabric Shelters have become a fixture on mine sites across the globe in recent decades. Short lead time, fast install, ability to relocate and lower environmental footprint all make them perfectly suited to the demands of the mining and resources industries.

DomeShelter Australia is a trusted, leading supplier of Shelter Solutions across Australia and internationally. Over more than 25 years, we have developed unparalleled expertise in designing and manufacturing Fabric Shelters that are engineered to protect people and assets from the elements – even the most remote and harsh conditions.