If you are working on a construction project, you may have come across the term “GA drawing”. GA drawings are an essential part of any structural project, and understanding them is crucial to ensure the successful completion of your project. However, many clients find themselves confused about what GA drawings are and why they are important.

In this article, we will explain what GA drawings are, why they are crucial, and why it is essential to review them quickly to ensure your project moves forward smoothly to the next stage.

What is a GA Drawing?

GA – General Arrangement – drawings provide accessibility and build options that are not build-ready but provide a framework for further discussions with customers, engineers and fabricators. Plan and elevation views are typically provided, as well as a 3-dimensional isometric view of the Structure.

General Arrangement drawings communicate sufficient detail for a Structure model to be understood without the viewer making assumptions. Only once a GA drawing has been reviewed and approved will fabrication drawings be produced. The information used to produce a GA drawing is gathered from quotes and initial consultations with clients.

What is the purpose of a GA drawing?

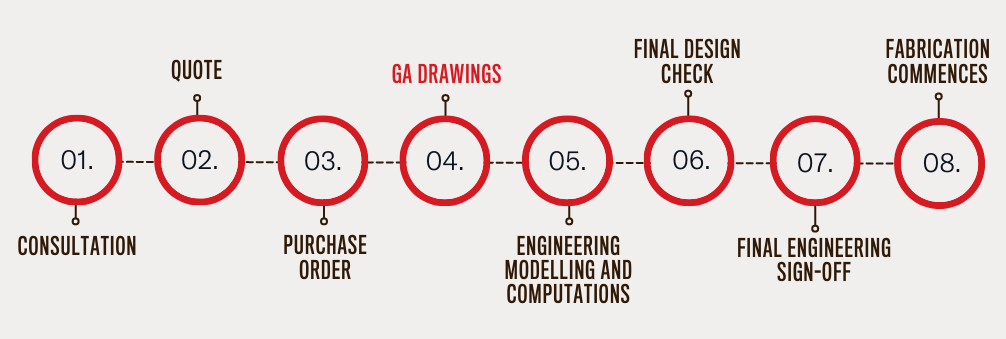

GA’s are the first deliverable after receipt of a Purchase Order (PO). They are necessary to confirm the design parameters of a planned structure and facilitate any necessary discussions. GA approval is essential before any engineering and further design work can commence.

What should clients look for when reviewing a GA drawing?

Clients should pay attention to all aspects of a GA drawing, as once these are approved fabrication will commence, at which stage it is difficult and costly to make changes.

Container height is a very crucial element that clients should review immediately on receipt of a GA drawing. Some clients may be unaware that sea containers come in multiple size profiles and ensuring the Shelter is fabricated to the correct container height is important.

Another suggested detail to review relating to Post-Mounted DomeShelter™ Structures is the placement of the posts, making sure columns will not obstruct existing infrastructure, doorways etc.

Other general areas to check include:

- Shelter width, length and height dimensions

- Container positioning and sizing

- Endwall design (if applicable)

- Wind rating/site location

In terms of DomeShelter Australia’s GA drawings, these elements are prompted within the Docusign platform that the GA drawings are sent through to ensure clients review each area.

What happens after clients approve a GA drawing?

Once a GA drawing for a DomeShelter™ Structure has been signed, an approved copy will be sent back to the team, and then your project will be prepared to be passed to the engineer. The engineer will then work on the modelling and computations prior to a check from our designers, then finally back to the engineer to sign off. Fabrication will then commence.

We cannot start production on a Shelter until the GA drawings have been signed off. If a client is under a strict deadline, the single best thing they can do to assist and ensure there are no serious delays in the project is to sign the GA drawing promptly. Projects are scheduled with precision, with a certain window of time allowed for review of the GA. A prolonging of this process can push back manufacturing slots and disrupt the rest of the project. In the past, projects have been delayed by as much as several months due to GA drawings going unsigned.

If you review your GA drawings and have any questions or concerns, you can contact the project assistant who sent the drawings to you.

In Conclusion

GA drawings are an essential aspect of any construction project, and it’s crucial to understand their importance. Clients should review GA drawings carefully and promptly, paying attention to all aspects, including container height, post placement, shelter dimensions, container positioning, endwall design, and wind rating/site location. Once a GA drawing has been approved, fabrication can commence. By signing off on GA drawings promptly, clients can help ensure that their projects stay on schedule and avoid costly delays.