Modern Fabric Structures are an evolution of the Nissen Hut, used extensively in the World Wars of the 20th century. A practical and logical shelter design, they reappeared in recent decades, attracting attention for their temporality and economy of materials. This article discusses the history, uses and benefits of Fabric Shelters.

Nissen Huts: The Precursor to Fabric Structures

Nissen Huts were prefabricated steel structures, comprised of corrugated iron sheets bent over a semi-cylindrical frame and planted in the ground, used extensively during the First and Second World Wars.

Two main factors informed the invention of Nissen Huts: Firstly, due to wartime material shortages, the design had to be as economical as possible. Secondly, they had to be portable and easily erected to respond to wartime needs. A basic prefabricated Nissen Hut could be packed into a standard army vehicle and erected in 4-6 hours by a small team.

After the war, Nissen Huts fell from favour, despite attempts to adapt their use for post-war purposes such as housing and workshops.

The Advent of Modern Fabric Structures

Steel sheds were the traditional and most common choice for storage and other industrial uses throughout the rest of the 20th century. However, as technologies progressed towards the turn of the century, leading to the development of tear-resistant and fire-retardant fabrics, a modern form of semi-cylindrical Fabric Structure emerged, fulfilling needs not met by traditional steel sheds.

Similar to Nissen Huts, contemporary Fabric Shelters are sought after for their economic use of materials in the cost-competitive modern market. They are also portable and easily installed on remote sites, increasing their desirability.

A modern-day Fabric Structure consists of semi-circular curved steelwork, secured at either end to steel posts or sea containers, covered with a membrane of durable coated Polyethylene fabric. The whole structure is fabricated off-site, packed down into kit form and transported to site for installation.

Fabric Shelter Size and Customisation

The curved steel roof structure provides structural integrity and increased strength for a clear span covered area up to 30 plus metres wide.

- Height is achieved by mounting on sea containers up to three high, with the arch providing additional height.

- Length is achieved by placing containers end to end for the required length. Starting at a minimum of around 6 metres, maximum length is virtually unlimited.

Additional features that can be added to Fabric Shelters include fabric End Walls, personnel or large equipment doors, sliding curtain walls, flooring systems, lighting, branding and other signage, and the list continues.

Common Uses of Fabric Structures

Fabric Structures are found across the globe, used often as alternatives to steel sheds for various purposes including:

- Workshops

- Warehouses

- Helicopter and aircraft hangars

- Sports arenas

- Logistics fleet maintenance and storage

- Manufacturing facilities

- Military field deployment Shelter solutions

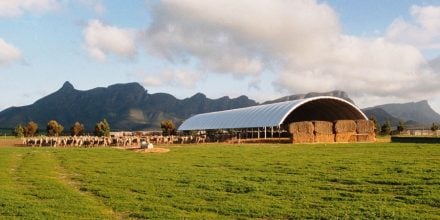

In Australia, they are mainly utilised in the mining and industrial sectors, with a small but increasing use in agriculture.

The non-permanent, portable dexterity of these Shelters provides a key advantage to companies seeking a quick and cost-effective solution to their shelter needs. They can be easily transported to site and installed in extremely narrow time frames. Additionally, for those working on land not owned by the company, the structure can be dismantled and reused elsewhere at the cessation of their contracted time.

Benefits of Fabric Structures

While steel buildings still have wide appeal, they are regarded as long-term, permanent installations, whereas Fabric Structures are non-permanent and portable. Because of this, they have become increasingly popular on worksites where contractors need to be agile in getting a shelter installed quickly, most often on land they don’t own, with a fixed term to completion of their contract. Often, a Shelter will be moved across the site as work needs change and, on completion of the contract, can be dismantled and stored for future use or sold in kit form to the next user. It is reported that overall project cost is reduced with the use of Fabric Structures compared to steel sheds.

In addition, the fabric membrane can often alleviate the need for lighting as natural light is able to pass through the fabric. They are also cooler than steel sheds in hot conditions, resulting in a more ergonomic shelter option.

Types of Fabric Structures

Fabric Structures have three distinct types, defined by the substructures onto which the fabric-covered arch is mounted:

An additional option exists with a combination of different mounting options, typically a combination of Posts and Containers.

The most common substructure type is Sea Containers. They offer a range of benefits, such as:

- Ease of transportation

- International standard sizing

- Easy securing/hold-down options

- Versatility, with the ability to be converted into office or storage space or staff amenity facilities.

The Durability of Fabric Structures

As a result of rigorous engineering standards, and with the intrinsic benefits of the arched roof and tough fabric membrane, Fabric Structures can be built to withstand significant natural and environmental hazards. Extreme wind, snow, heat and cold can be accounted for to ensure the structural integrity of the final product in almost any extreme environmental situation.

DomeShelter Australia

DomeShelter Australia’s Fabric Structure design is unique, the result of over 25 years experience and innovation. We are now one of the world’s leading Fabric Shelter manufacturers and suppliers, with over 6500 kits delivered to remote Australian sites, as well as over 30 countries internationally.

If you would like more information about DomeShelter Australia’s Shelter Kits, contact our friendly customer service team on 1300 193 188 or visit Request a Quote to submit your enquiry.