In today’s ever-evolving business landscape, the transport and logistics industry faces a series of challenges that demand innovative solutions. From labour shortages to natural disasters and the rising cost of warehousing & fuel, the industry is navigating through uncharted territory. Moreover, the growing demand for sustainability and the constant shift in customer expectations add to the complexity.

In this article, we will outline the top 6 challenges facing the transport and logistics industry and explore some strategies to effectively manage them.

1. Labour Shortages

The growing skills/labour shortage is a big topic on the mind of many businesses in 2023, not just in transport & logistics, but all sectors. 90% of businesses expect to be affected by staffing shortages in 2023, according to a survey by Ai Group. Although this is a universal issue across sectors, NAB reports that “Transport & Storage & Construction are being most impacted”.

An increase of skilled migrants post-covid is expected to help manage this challenge, as well as companies investing in in-house training and upskilling to help businesses get the most from the workforce skills base that they already have or can realistically hire.

The labour shortage has had a considerable effect on the building and construction industry, having flow-on effects that impact other sectors with extremely prolonged lead-times for buildings and infrastructure. Investigating alternatives to traditional building types is essential for businesses to efficiently expand their infrastructure and bypass these lead time issues.

2. Natural Disasters

Increasingly unpredictable weather patterns and frequent disaster-level events have revealed a serious challenge facing the transport and logistics industry. Flooding in early 2022 caused severe disruptions to rail services on the strategic East-West corridor linking the eastern states to Western Australia.

Severe weather conditions can cause significant damage to physical infrastructure, leading to the destruction of roads, bridges, and tunnels, and disrupting shipping routes and speeds. Even in milder cases, adverse weather patterns can still affect drivers, causing low visibility and traffic congestion on busy roads, resulting in costly delays to normal shipping operations.

Creating disaster response and recovery plans, practising consistent supply chain risk management, diversifying carriers and routes, as well as government intervention and assistance strengthening key road and rail infrastructure will be crucial to managing the risk posed by natural disasters in the transport and logistics industry into the future.

3. Rising Cost of Warehousing

Industrial rent has increased an average of 14.9% year-on-year nationally, according to JLL. This combined with increasing construction costs, wage costs, land costs and prolonged building lead times is making the building or renting of warehouse space more difficult.

Transport and logistic companies will need to seek cost-effective alternatives to respond to a lack of warehouse space that still ensures goods will be protected. Automated warehousing is one potential solution to optimise existing space as best as possible.

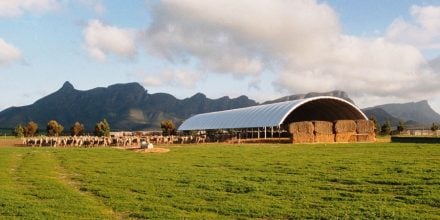

Fabric Shelters offer a modern, cost-effective solution to increase storage space and keep assets protected from the elements. Quick turnaround and easy installation while remaining durable and weatherproof makes them a desirable alternative to traditional building types. Fabric Shelters are uniquely well-suited for warehousing; their unique tensile design means internal support poles aren’t required, resulting in a clear-span interior with extra-tall height clearance for maximised storage space.

4. Sustainability Expectations

A sustainability strategy is becoming essential for any business that wants to build a positive reputation and attract customers. In 2022, a survey conducted among Australian consumers revealed that over 38 percent of those surveyed always considered sustainability in their purchase decisions. PwC reports that the transport and logistics industry is making slow progress towards better sustainability: CO2 emissions from road freight transport have risen by more than 20 percent since 1995, even though vehicles are more efficient today.

A more emissions-conscious approach to project and transport route management, the growth of parcel collection point networks, and the widespread adoption of electric vehicles are all instrumental in helping the industry to improve its sustainability. Supply Chain Quarterly specifically points to designing/redesigning warehouses and distribution centres to minimise buildings’ footprints as a key innovative strategy to improve sustainability efforts.

Fabric Structures are a modern, environmentally-forward alternative to traditional building types that provides safe and protected storage space with a lower environmental footprint. Less intensive hold-downs and options available that eliminate the need for ground disturbance and the ability to relocate Shelters multiple times throughout their lifespan make them a desirable choice for meeting environmental expectations.

5. Shifting Customer Expectations

Forbes details new consumer behaviours and expectations that have emerged in the last three years in reference to the transport and logistics industry. “Most significant is the expectation for faster delivery, particularly the demand for same-day delivery, which is putting additional pressure on the industry”.

The establishment of smaller ‘satellite’ warehouses by carriers is the main suggested mitigation strategy for businesses to respond to this rising expectation. Diversifying delivery options, especially in urban areas, with third-party contractors the likes of Postmates, can also help to ensure swift service.

6. Rising Fuel Costs

One of the most significant challenges facing the Transport and Logistics industry in 2023 and beyond is rising fuel prices. The logistics industry relies heavily on fuel through every step of the supply chain. Fluctuations in price are caused by natural disasters, war, conflict, global supply and demand, exchange rates, and the list continues.

To handle the increase in fuel prices, many Transport & Logistics companies increase their prices to compensate, or introduce surcharges. Other solutions may include providing additional payments to Franchise Partners to help cover increased fuel prices, reducing the frequency of delivery services or their service areas to establish more efficient transport routes or shorten the distances their trucks are required to drive.

How Merkanooka Haulage Ensure Efficient Operations with a DomeShelter™ Structure

Merkanooka Haulage, a WA-based transport company supporting the mining and agricultural sectors, operate a large truck fleet 24 hours a day, 7 days a week.

They required a workshop for heavy vehicle maintenance to help sustain this day-long capability. The workshop was to be located in the remote WA goldfields region, close to Merkanooka’s key mining clients.

A Container Mounted DomeShelter™ Structure was provided to fulfil their need for efficient workshop space. The workshop keeps their loaders and prime movers running without the need for equipment to be transported off-site, which helps them avoid costly delays.

It is also located on land not owned by Merkanooka Haulage; the impermanent and relocatable nature of Fabric Shelters made DomeShelter Australia the idea choice to ensure optimum through-life.

In Summary

The transport and logistics industry is navigating through a complex landscape, facing challenges that demand proactive and innovative approaches. Labour shortages, natural disasters, rising warehousing costs, sustainability expectations, and evolving customer demands require careful consideration and strategic planning. The adoption of Fabric Shelters as a practical solution offers numerous advantages, from providing cost-effective and weather-resistant warehousing to meeting sustainability goals.

For those looking to navigate these changes more efficiently, DomeShelter Australia provides durable, fully-engineered Fabric Shelters, designed and manufactured in Australia and transported to sites across the world. To learn more about what’s possible with a DomeShelter™ Structure, you can utilise the free 3D Designer on our website and design your own Fabric Shelter.