The mining industry has a reputation for inherent risks and potential health hazards, which are varied and sometimes significantly consequential. It is crucial for companies operating in this industry to prioritize the safety and well-being of their employees. A report by KPMG found that 54% believe the mining industry “needs to consolidate to manage costs and risks more effectively going forward”.

Strict safety legislations and protocols surround the mining industry, with companies striving towards zero harm. In this article, we will explore the top 10 safety risks for the mining industry and provide strategic insights on how to mitigate these effectively.

1. Chemical Hazards

Mining operations often involve exposure to hazardous chemicals, such as toxic substances and harmful gases. These substances can pose serious health risks, including chemical burns, respiratory problems, and poisoning.

Proper handling procedures, comprehensive risk assessments, and the use of appropriate personal protective equipment (PPE) are crucial in mitigating chemical hazards. Mine sites should have various Standard Operating Procedures (SOPs) to address the correct use of PPE, safe handling, use and disposal of the various chemicals workers may encounter in their work. Ventilation is also an important factor in minimising exposure danger. Finally, secure, dedicated storage of chemicals and other hazardous materials is vital to ensure safe and controlled environments around chemical use.

2. Equipment and Machinery Accidents

Mining vehicles and other machinery have the potential to cause serious harm when not operated or maintained correctly. Correct use and maintenance of mining equipment are vital to prevent accidents and injuries.

Comprehensive training programs, strict adherence to operating procedures, regular equipment inspections, and the use of safety devices such as emergency stop buttons are essential safety measures to mitigate risks.

3. Heat Stress

Mining related work can involve prolonged time spent outside, with many mine sites located in desert environments. Working in high-temperature environments can lead to heat-related illnesses. Overexposure to heat and humidity can cause the body to become fatigued and distressed. This can result in heat stroke or even more serious ongoing health problems.

Where there is a possibility of heat stress occurring, companies need to carry out a risk assessment that considers the work rate, working climate and worker clothing and respiratory protective equipment.

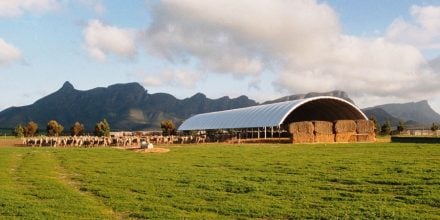

Providing adequate ventilation, hydration programs, rest breaks, and training on recognizing and managing heat-related conditions are crucial preventive measures. Providing dedicated Sheltered work areas can also help minimise this.

4. Explosions and Fires

The use of explosives and flammable materials in mining operations increases the risk of explosions and fires. Implementing strict storage and handling protocols, conducting regular safety inspections, and maintaining firefighting equipment and evacuation plans are essential safety measures.

5. Air pollution

Exposure to pollutants such as coal dust and silica can lead to severe respiratory illnesses. Implementing proper dust control measures, including ventilation systems and dust suppression techniques, is crucial for protecting miners from airborne particulates.

6. Whole Body Vibration

Prolonged exposure to excessive vibration can cause musculoskeletal problems and other health issues. This can occur when operating Heavy Machinery, which is often associated with mining operations.

Smoothing vehicle paths, ensuring optimal equipment condition to ensure smoother operation, and limiting exposure to vibration-heavy machinery are effective ways to reduce whole-body vibration.

7. Electrocution

Electrical hazards pose a significant risk in mining operations. Any cuts or breaks along an electrical system could pose an electrical hazard to nearby workers. Limited visibility caused by rough terrain or night-shift work can mean workers may not see exposed wires until it’s too late.

Regular equipment inspections, checking for exposed wires, and using electricity-resistant PPE are essential preventive measures.

8. UV Exposure

Miners working in open-pit environments are at risk of overexposure to harmful UV radiation. Sun exposure is a serious concern; not only can UV overexposure lead to skin cancers, but it can also cause eye damage, dehydration, headaches and nausea.

Employers should conduct risk assessments to develop appropriate sun protection measures, including PPE and sunscreen application. Providing shaded areas for staff to work within wherever possible is critical to ensure UV exposure is mitigated on mine sites.

9. Manual Handling

Manual handling and body stressing are common causes of musculoskeletal disorders in the mining industry and contribute to many workers’ compensation claims. Proper training in lifting techniques, providing mechanical aids, and implementing ergonomic workstations can help prevent these injuries.

10. Noise Exposure

Miners are often exposed to high levels of noise, which can lead to hearing loss and other auditory disorders. Exposure to loud noise can also cause high blood pressure, heart disease, sleep disturbances, and stress. Implementing engineering controls such as noise barriers and soundproofing, as well as providing appropriate hearing protection devices, are essential in mitigating noise-related risks.

In Conclusion

In conclusion, the mining industry poses specific risks that require focused safety measures to protect workers’ well-being. By addressing these ten common risks through comprehensive safety protocols, training programs, risk assessments, and the implementation of preventive measures, mining companies can create safer work environments and prioritize the health and safety of their employees.

As Nick Harridge of KPMG Australia comments: “Social and investor expectations towards ESG (Environmental, social, and corporate governance) are pushing miners to invest in innovative ways and adapt at a faster pace. We expect the opportunity to commercialize new technologies will continue to fuel more innovation and investment, further increasing the pace of change. This is an exciting time for the mining industry”.

For more information about how a modern Shelter Solution can protect your people and assets, visit the Learning Centre on our website.